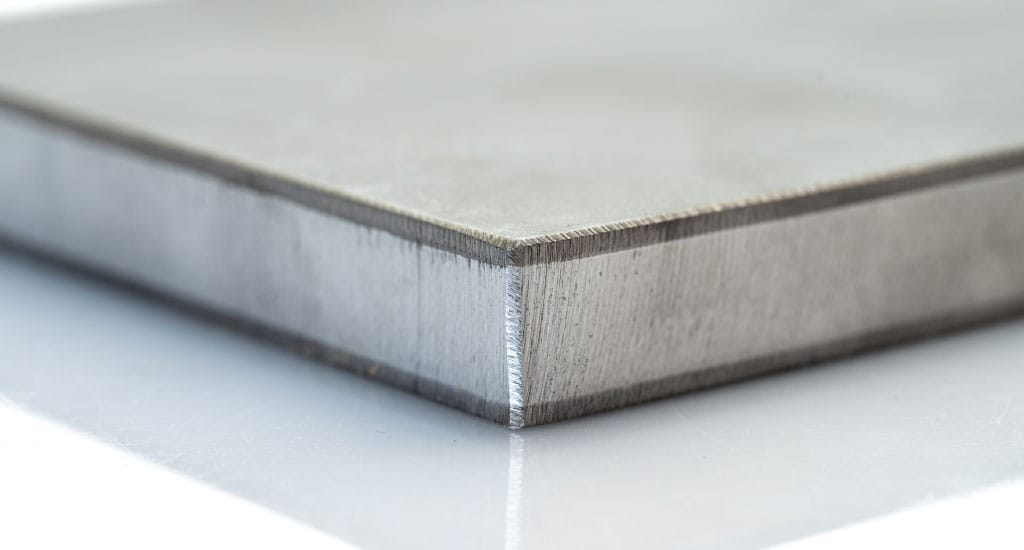

Clad or Bimetallic Plates

Clad or multilayer steel plates are a type of composite material made by combining two or more different metals to achieve optimal mechanical, chemical, and economic properties. These plates typically consist of a base metal, such as carbon steels like ST52 or A516, and a corrosion-resistant cladding layer made of stainless steel, nickel, titanium, and others. The combination of these metals results in a product with high resistance to corrosion, pressure, and heat, while significantly reducing costs compared to fully alloyed plates.

Chemical Composition of Clad Plates

The chemical composition of clad plates depends on the metals used in each layer. Below are common examples of base and cladding material compositions:

Base Metal Chemical Composition

| Steel Grade | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|

| ST52 | 0.20% | 1.60% | 0.55% | ≤ 0.035% | ≤ 0.035% |

| A516 Gr 70 | 0.30% | 1.30% | 0.35% | ≤ 0.035% | ≤ 0.035% |

Cladding Material Chemical Composition

| Cladding Grade | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Key Feature |

|---|---|---|---|---|

| Stainless Steel 304 | 18–20% | 8–10.5% | – | General corrosion resistance |

| Stainless Steel 316L | 16–18% | 10–14% | 2–3% | Excellent resistance in chloride and chemical environments |

| Titanium Grade 2 | – | – | – | Exceptional acid resistance, lightweight |

Clad Plate Manufacturing Process

The production process involves the following stages:

–

- Incoming Material Quality Control

Base and cladding plates are delivered to the plant and thoroughly inspected to ensure compliance with technical specifications - Grind Mating Surfaces

The contacting surfaces of both plates are ground to remove oxides and surface impurities, ensuring proper bonding. - Assembly of Plates and Explosives

⦁ The cladding plate is positioned above the base plate with a precise standoff distance.

⦁ Special explosives are evenly spread over the top plate.

⦁ This setup allows the formation of a metal jet during detonation.

Explosion Welding

⦁ The detonation generates a high-velocity, oblique collision between the plates.

⦁ The jet cleans the interface by removing impurities.

⦁ A strong metallurgical bond is formed at the interface. - Post-Weld Heat Treatment

Heating is applied to reduce residual stresses and stabilize the microstructure. - Flattening

The bonded plates are leveled and straightened for further processing. - Cutting and Finishing

The plates are cut to final dimensions based on customer specifications. - Testing and Inspection

⦁ Ultrasonic testing ensures the integrity of the bond.

⦁ Dimensional and quality certifications are issued. - Marking

Plates are marked with identification numbers and technical data. - Packaging and Delivery

Finished plates are securely packed and prepared for shipment.

Technical and Economic Advantages

⦁ Cost Efficiency: Use of expensive metal only on the surface layer

⦁ High Resistance: Excellent performance against corrosion, abrasion, and high temperatures

⦁ Extended Equipment Life: Suitable for harsh industrial conditions

⦁ Improved Workability: Easier to weld and form than full alloy plates

⦁ Standards Compliance: Meets ASTM, ASME, EN, and DIN standards

Industrial Applications

- ⦁ Oil, Gas & Petrochemical: Pressure vessels, heat exchangers, pipelines

- ⦁ Power Plants: Boilers, turbines, high-temperature components

- ⦁ Chemical, Food & Pharmaceutical: Corrosive environments

- ⦁ Marine Industry: Offshore structures, shipbuilding

- ⦁ Steel & Cement: Kilns and material transport systems

Alloy Steel Combinations with Clad

- ⦁ A516 + 316L: For high-pressure and acidic environments

- ⦁ ST52 + Titanium: Excellent resistance in marine environments

- ⦁ Clad with Hardox: Outstanding abrasion resistance

Leading Manufacturers

- ⦁ China: TISCO

- ⦁ Japan: Nippon Steel

- ⦁ USA: NobelClad

- ⦁ Germany & Austria: Thyssenkrupp, Voestalpine

- ⦁ India, Korea, Russia: Rapidly growing capabilities

The Future of Clad Technology and the Role of SSAB STEEL SAZEH

Advanced technologies such as laser cladding, powder deposition, and hybrid welding are gaining ground in clad plate manufacturing. SSAB STEEL SAZEH, through direct imports from China, offers high-quality Clad plates at competitive prices. In addition to supply services, the company also provides technical and consultancy support.